Strategic Modular Workforce Housing Solutions: Efficiency and Comfort for Remote Sites

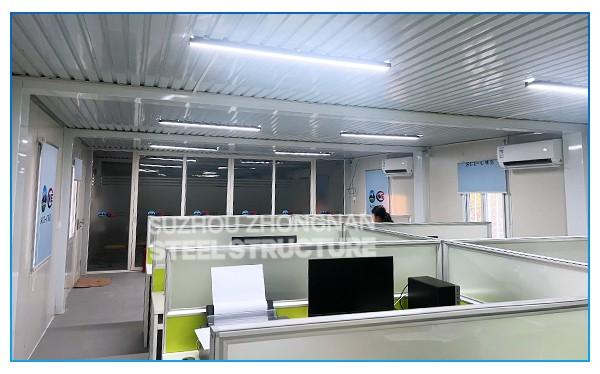

Managing remote operations in industries such as mining, oil, or construction demands much more than a well-coordinated scheme. It also calls for a safe and cozy setting for those working on the ground. In the past, staff accommodation in severe environments used to be a slow and costly affair. Nowadays, modular workforce housing solutions have revolutionized how firms consider site infrastructure. These buildings basically provide a mixture of quick deployment, strong frame, and low running costs over time. Moving building work from the site to a controlled factory environment, a company can guarantee a better standard of living and still comply with the tight project schedule.

I am a Senior Technical Consultant at ZN House. My professional journey at ZN House has spanned over 7 years, where I have accumulated significant expertise in modular architecture and remote site logistics. My entire career has been a commitment to enhancing the quality of life on-site. I have been personally responsible for the deployment of hundreds of thousands of units in various challenging environments, ranging from tropical rainforests to areas with high seismic activity. I concentrate on engineering and design that is human-centric to bring the best out of both worlds, so that every one of our durable prefab site accommodation projects is not only safe but also comfortable.

The Engineering of Durable Prefab Site Accommodation

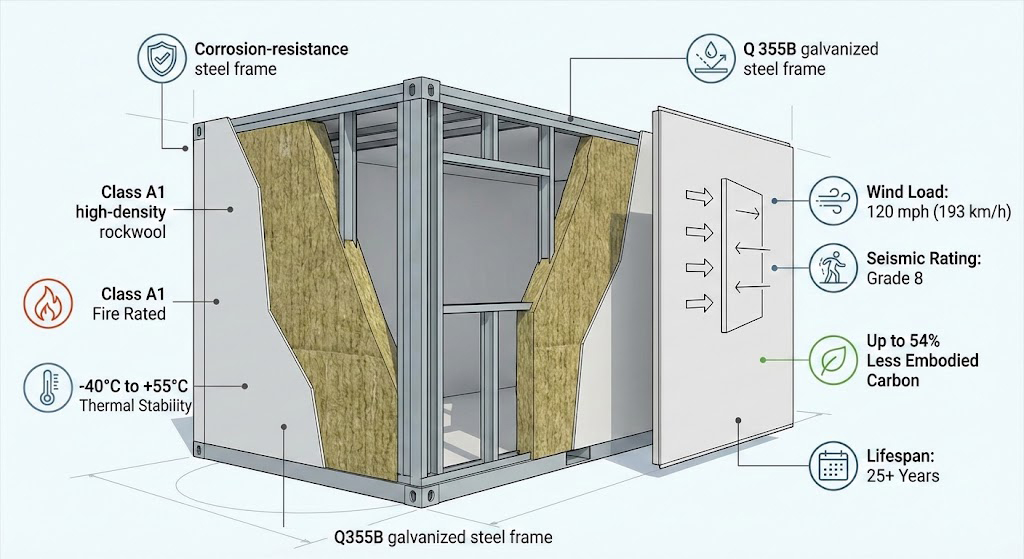

Employees can only work efficiently if they have been well-rested. The very best Modular Workforce Housing Solutions are made in a way that they can survive being exposed to extreme natural elements. A large majority of the housing is equipped with Q355B galvanized steel frames. It ensures a marine-grade level of corrosion resistance. Additionally, the exterior walls contain high-density rockwool insulation. The fire rating of this material is Class A1. It also allows the indoor temperature to be practically the same as the outdoor one within a wide temperature range from -40°C to +55°C.

Recent research conducted by scholars from the University of Cambridge and Edinburgh Napier University shows that modular construction can have up to 54% less embodied carbon per square foot when compared to traditional methods. This great efficiency doesn’t come from compromising on the strength of the units. In fact, such units are usually certified to withstand wind loads of up to 120 mph and seismic activity of Grade 8.

| Component | Specification | Strategic Advantage |

| Main Frame | Q355B Galvanized Steel | High strength and corrosion resistance |

| Insulation | Class A1 Rockwool / PIR | Superior fire safety and thermal control |

| Wind Load | 120 mph (193 km/h) | Withstands hurricanes and severe storms |

| Seismic Rating | Grade 8 | High safety in earthquake-prone regions |

| Lifespan | 25+ Years | Long-term asset value and reliability |

Table 1: Technical Specifications of Modular Units

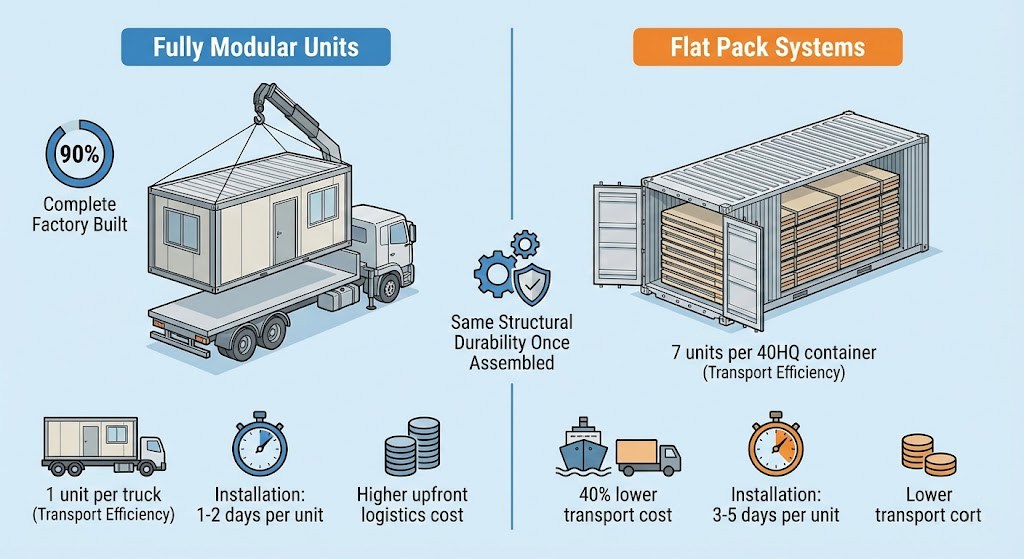

Comparing Configurations: Modular vs. Flat-Pack

Choosing the right temporary modular housing for remote workers depends on your logistics. Fully modular units are nearly 90% complete when they leave the factory. They offer the fastest “plug-and-play” experience. However, flat-pack systems are optimized for shipping. You can fit up to seven units in a single 40HQ container. This reduces freight costs by nearly 40%. Both systems provide the same structural durability once assembled.

| Feature | Fully Modular Units | Flat Pack Systems |

| Installation Speed | 1-2 days per unit | 3-5 days per unit |

| Transport Efficiency | 1 unit per truck | 7 units per 40HQ container |

| Logistics Cost | Higher upfront | 40% lower transport cost |

| Best Application | Urgent high-density needs | Remote, high-volume projects |

Table 2: Deployment Comparison: Modular vs. Flat-Pack

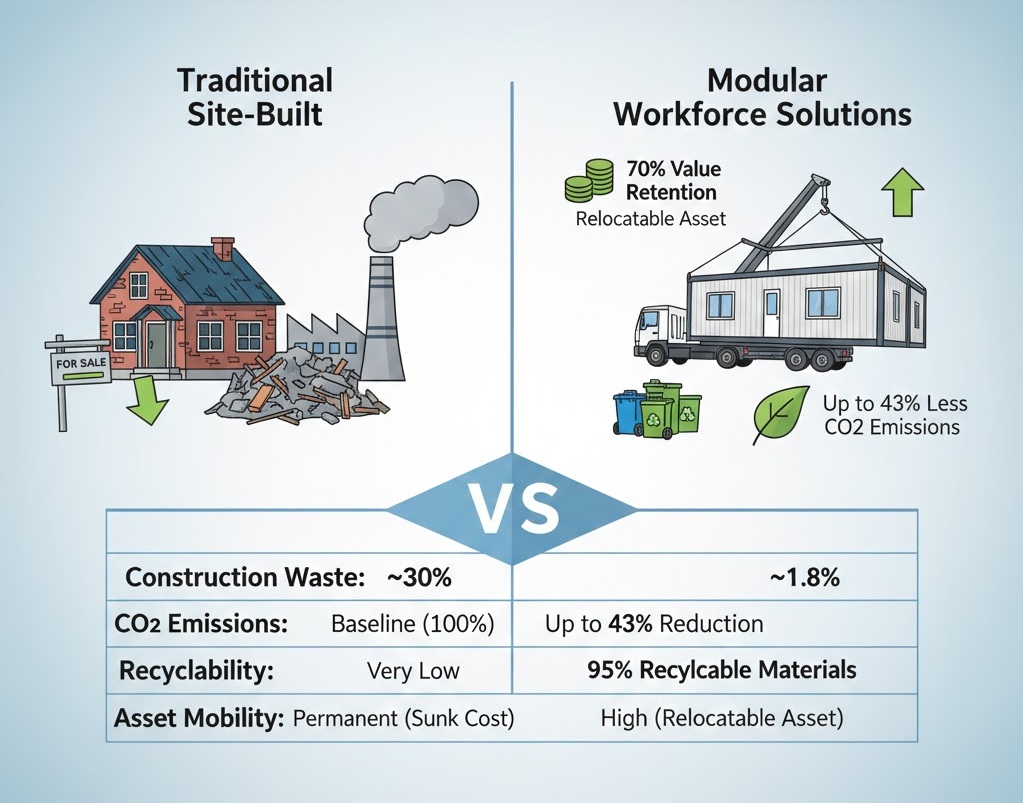

ROI and Sustainability in Workforce Housing

It makes financial sense to put money into remote workforce housing that is environmentally friendly and energy-efficient. Normally, when you build brick and mortar houses, you gradually lose the value of the property, no matter how well you maintain it. The situation they will be in is like houses that get old and worn out. But modular units are different in a way that you can think of them as movable assets. It has been found that they keep almost 70 percent of their original worth. You can even dismantle them, relocate them, and reassemble them at different project sites.

The Modular Building Institute states that off-site manufacturing can cut construction waste to only 1.8%. This is a significant change from the 30% waste that is usual for on-site builds.

| Metric | Traditional Site-Built | Modular Workforce Solutions |

| Construction Waste | ~30% | ~1.8% |

| CO2 Emissions | Baseline (100%) | Up to 43% Reduction |

| Recyclability | Very Low | 95% Recyclable Materials |

| Asset Mobility | Permanent (Sunk Cost) | High (Relocatable Asset) |

Table 3: Environmental and Financial Impact

Real-World Case Studies

Case Study 1: The Southeast Asian Tunnel Project

Location: Remote Jungle, Vietnam

Time: early 2023

The Problem: The site was situated in a jungle basin with very high humidity and no access for heavy vehicles. Practically, traditional construction could not be done because of the terrain. In addition, regular prefab units would quickly become moldy and corroded in 95% humidity.

The Solution: Among other things, I personally managed the deployment of specialized units with a high-density flat-pack configuration. This enabled us to carry units with small track vehicles. I required the application of marine-grade anti-corrosive coatings and an advanced moisture-barrier floor system. The team and I oversaw the manual-assisted assembly. We built the 200-person village in only 14 days without the use of a single heavy crane.

Testimonial: “ZN House figured out a logistical nightmare that had held our progress up for weeks. Besides the fact that the Modular Workforce Housing Solutions were delivered on schedule, notwithstanding the terrain, the comfort levels really lifted our crew’s morale. We have completely changed our perspective on site housing.”

— Nguyen Van, Logistics Manager, Indochina Infrastructure Partners

Case Study 2: The Northern Territory Thermal Safety Project

Location: Australian Outback

Time: 2024

The Problem: Terra Australis Mining was on the brink of a major safety disaster. Around them, it was so hot that the weather temperatures often went above 50°C. The temporary accommodations that the company offered to staff were not properly insulated. Heat strokes became a common occurrence, and the company’s expenses for running the diesel generators for air conditioning were astronomically high.

The Solution: I designed a super-efficient cluster of Modular Workforce Housing Solutions for very cold or hot conditions. We used 100mm Class A1 rockwool insulation along with reflective exterior thermal barriers. Also, I was in direct contact with the client to come up with solar-ready roof trusses. This feature enabled the units not only to accommodate but also to support quite heavy PV panels. Through that, the internal temperature was kept steady at 22°C, and site energy consumption saw a 40% decrease.

Testimonial: “It was massive overheads and worker fatigue that were our main issues, but things changed after we talked to the team at ZN House. The thermal efficiency of the units was a complete game-changer. Our energy bills went down right away, and even more importantly, the number of our safety incidents due to heat came down to zero.”

— Sarah Jenkins, Site Director, Terra Australis Mining

Conclusion

Modular Workforce Housing Solutions will be the mainstay of industrial accommodation. They offer a rare combination of rapidity, sustainable nature, and employee well-being. High-quality materials combined with efficient supply chain management are the key factors in enabling companies to safeguard their most valuable asset, their people. ZN House keeps pioneering the global supply of such turnkey environments.

Ready to make your site logistics more efficient?

We at ZN House specialize in designing tailor-made solutions for the toughest industries in the world. Feel free to get in touch with our experts for a no-cost technical consultation regarding your upcoming project.

FAQs

How do modular units perform in extreme climates?

Units feature high-density rockwool or PIR insulation. Besides that, double-layer vacuum glass and reflective coatings are employed. Altogether, these characteristics keep the internal temperature stable even in extreme exterior temperatures up to -40°C or +55°C.

Are modular workforce buildings easy to relocate?

Yes. One of the main advantages of Modular Workforce Housing Solutions is their mobility. Nearly all, about 95%, of the parts are recyclable. Hence, you can take the units apart and bring them to a new location without the structure’s wear and tear.

How long does modular site accommodation last?

The reason why these units can be reliably used for more than 25 years is that they are made out of Q355B galvanized steel frames and industrial-grade coatings. Besides, they need almost no maintenance at all in comparison with traditional structures.

Disclaimer: Technical information and materials that appear in this article are taken from one of ZN House’s containers manufactured in-house; specifications, materials, and technical data may vary due to custom requirements.