Why Western Sites Choose Flat Pack Containers – China’s Supply Chain Edge

In many Western construction sites, a neat row of flat pack container units stands ready. Each flat pack container serves a purpose. Some act as site offices. Others become dorms or meeting rooms. Some turn into kitchens or bathrooms. The flat pack container offers a full, modular solution for temporary needs.

Flat Pack Container as Modern Site Infrastructure

The flat pack container is a prefabricated module that arrives ready for use. You assemble it on site—no need to start from scratch. There’s no compromise on quality. You save time and cut costs.

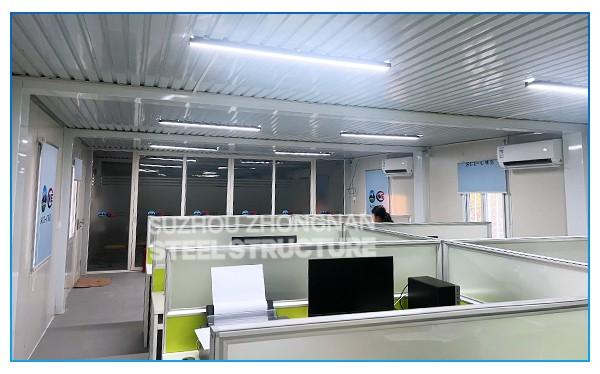

Today, it has replaced the outdated steel huts still seen in some projects. It offers superior style, safety, and speed. Designed for adaptability, it performs well in various climates and suits many project types. It’s used across highways, bridges, rail lines, wind and solar farms, and energy plants. It serves as offices, dormitories, canteens, storage units, even labs, and first-aid rooms.

Why Developed Markets Favor Flat Pack Container

Developed markets set strict rules. They demand safety, comfort, and compliance. They check wind load, seismic resistance, fire rating, and insulation. This modular solution meets all those standards. With a robust steel frame, reliable connections, and standardized shipping, it arrives ready and clears inspections quickly.

It also supports green goals. You can reuse it multiple times, recycle components at the end of life, reduce waste, and lower your carbon footprint—all while meeting sustainability targets.

Trade-off: Speed vs. Standardization

Many builders still pick steel huts. They value low cost and speed. They set up huts during the day. They tear them down in days. They work under tight schedules. Yet they face safety gaps. They face short lifespans. They face higher operating costs over time.

The flat pack container may cost more up front. Yet it pays back in lower rents, fewer repairs, and lower disposal fees. It balances speed and standardization. Each flat pack container unit installs in hours. Each unit connects quickly to power and water. Each unit supports HVAC, lighting, and wiring.

The Supply Chain Behind Flat Pack Container

The true power of this modular solution lies in its supply chain. Many assume these units come from local shops. Yet most of those seen on Western sites originate from China. With more steel production, more factories, and stronger logistics networks, China delivers a full solution, not just a box.

Manufacturers there handle everything in-house: welding the frame, fitting insulation, installing windows, and adding finishes. They manage doors, plumbing, and electrics. Each unit is fully tested, packed flat for shipping, and loaded into sea containers or onto flat racks. All customs documents are prepared in advance.

Chinese suppliers often ship within 15 days, while European makers may take 30–45 days. Local delays add cost and downtime. In contrast, the flat pack container from China arrives faster, reducing idle time on site.

Why Western Clients Choose “Made in China”

Western clients seek “Made in China” flat pack containers for four reasons:

Complete Industry Chain. China has robust steel, welding, finishing, and assembly industries.

Fast Response. Factories can mass-produce dozens of units in weeks.

Global Logistics. China’s ports and shipping lines can send modules worldwide.

Cost Advantage. Even with freight, the total price beats local offers.

Clients still get customization. They choose size, layout, and color. They ask for office desks or bunk beds. They specify bathroom fittings. They order insulation levels for Nordic winters or Gulf summers. They get exactly the right flat pack container for their project.

Case Study: A European Energy Project

In a French wind-farm project, the client needed CE-certified flat pack container units. They wanted offices, dorms, and a medical room. They demanded full insulation, HVAC, and fire suppression. The timeline was tight: 50 days from contract to delivery.

ZN House took action. The design team drew plans in three days. The factory cut steel and welded frames in ten days. Teams installed windows, doors, and panels in another ten days. Electricians and plumbers finished in seven days. Logistics partners booked space on a vessel. The units sailed and arrived in 14 days. Customs cleared them in two days. The site crew set up each flat pack container in eight hours. The entire project met the deadline. The site manager praised the speed and quality. The client reduced site idle time by two weeks. The project saved 20% in total site costs.

Benefits Beyond the Box

A flat pack container is more than a portable room. It is a building service model. You can connect units to halls or labs. You can stack them into multi-level blocks. The steel frames allow up to three stories. You can treat the modules as Lego bricks. You can reconfigure them on the fly.

Each flat pack container retains value after one project. You ship it to the next site. You rent it out again. You sell it on a second-hand market. You cut down on landfill.

Future Outlook for Flat Pack Container

As global projects raise the bar on site housing, this modular solution will shine even more. Builders will seek higher insulation, solar panels, smart controls, touchless entry, and IoT monitoring. It’s ready for the challenge, adapting to new technologies and aligning with green regulations.

China’s supply chain will evolve as well. Factories will adopt robotics, use digital twins, and track each unit from production to deployment. They’ll offer service contracts, remote diagnostics, and manage spare parts with precision.

Already a symbol of fast, high-quality, global delivery, the flat pack container will expand its role in infrastructure, oil and gas, mining, disaster relief, and high-tech projects. It will travel by ship, train, and truck, reaching deserts, jungles, and cities alike.

Conclusion

The Western love for this modular solution stems from more than style. It reflects deep changes in site demands. Safety, speed, sustainability, and flexibility now drive decisions, and this format delivers on all four. Backed by China’s mature supply chain, it proves that complex modular systems can be both high-quality and fast.

In the years ahead, you’ll see it on more sites, serving more workers and managers. It will redefine what a temporary building can be and symbolize global delivery strength. A single flat pack container tells the story of modern construction and shows how supply chains shape the built world.