Container Camps & Dormitories: Fast, Safe Housing for Workforces and Relief

Container camps deploy in days, not months. Start with a clear program—sleeping, WASH, kitchen, clinics, admin, storage—and choose the right system: foldable for speed, flat pack for scale, expandable for comfort. Budget by structure, insulation, MEPs, finishes, and logistics—not just the box price.

What is a “container camp” (and when to use it)?

A container camp is a modular village built from pre-engineered units: sleeping container dormitory, container classroom, admin container office, kitchen/dining, WASH blocks (shipping container toilets and showers), clinics (container hospital pods), and storage. Uses include:

- Refugee camp and disaster relief containers after storms, floods, or quakes

- Mining camp near extraction sites; agriculture camp for harvest peaks

- Soldier camp / solider camp for training or remote deployments

- Customized camp for events, construction, or temporary housing

Because everything is prefabricated (prefabricated construction), quality is consistent and scaling is simple.

System choices: flat pack, foldable, expandable

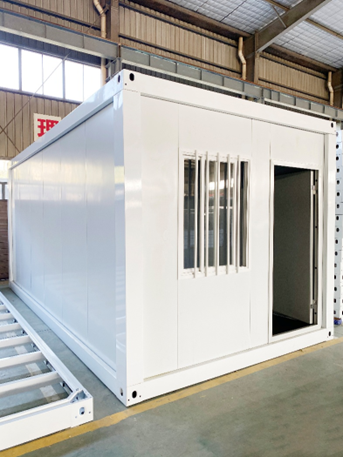

- Flat pack container house / office

Ships as panelized kits from a flat pack container house factory; best freight density and very repeatable on-site assembly. Ideal for 50–1000 bed camps and standardized facilities. - Foldable (collapsible) container house

Arrives as a folded unit that unfolds in hours—perfect for rapid response, pop-up classrooms, or urgent WASH. Great for emergency containers. - Expandable container house

Slides out to increase width for better livability—good for long-term dorms, clinics, and admin suites where comfort matters.

All three are supported by major container house manufacturer networks (domestic and container houses China / chinese container house). Choose by timeline, scale, climate, and local code.

Core modules you’ll need (program first, boxes later)

- Dormitories

- Container dormitory (20- or 40-ft), container van dormitory for transport fleetsBunk count by aisle width and egress code; lockers under bunks save space

- For women’s quarters and managers, upgrade privacy partitions and acoustic doors

- WASH blocks

- Container toilets for sale from verified toilet container suppliers

- Non-slip floors with coved skirting; waterproof wall panels; proper vent stacks

- Separate grey/blackwater lines; local septic, MBBR/MBR or holding tanks as required

- Kitchen & dining

- HACCP-friendly finishes; grease traps; screened intake air; shaded queuing areas

- Clinics / first-aid / container hospital pods

- Triage, treatment bay, clean/dirty flows; isolation room with extractor and HEPA

- Education / training

- Container classroom for inductions, literacy, and upskilling; 300–500 lux lighting, fresh air, and low-noise HVAC

- Admin & security

- Container office for HR, logistics, and site control; access gates, turnstiles, perimeter lighting

- Storage & utilities

- “Industrial container & supply” hubs for spares, PPE, tools

- Gensets, ATS, fuel storage; water storage and treatment; waste handling

Three proven camp layouts (textbook arrangements)

A) Rapid relief hub (≈50–120 people)

- 4–8 foldable dorm units (10–12 bunks each)

- 2 WASH containers (toilets + showers)

- 1 clinic pod + small container office

- Galley + shaded dining tent

- Why: fastest deployment, minimal crane time, simple foundations

B) Workforce village (≈250–400 people)

- 12–20 dorm containers (flat pack), stacked where allowed

- 3–4 WASH blocks split by zone; laundry container

- Galley + dining hall (double-wide or expandable)

- Admin suite (meeting, HR, IT), first-aid clinic

- Why: best unit economics and repeatable QC for long projects

C) Long-term base (≈800–1500+ people)

- Expandable dorms for supervisors; standard dorms for crew

- Central kitchen/dining, gym/recreation, multi-faith room

- Medical wing (triage + pharmacy + telemed)

- Fire roads, hydrants, water treatment, solid waste yard

- Why: comfort and welfare reduce turnover and incidents

Circulation rule of thumb: clear fire lanes, wayfinding, shaded walkways, and dusk-to-dawn lighting with motion sensors.

Dorm design that people actually sleep in

- Ventilation & air: Fresh-air rates per person; cross-vent windows; quiet split-ACs

- Acoustics: Heavier doors, door sweeps, and partition upgrades (soundproof shipping container package)

- Lighting: Warm task lighting at bunks; sleep-friendly low-glare general lighting

- Hygiene: Locker zones, boot racks, handwash at entries, easy-clean finishes

- Privacy: Curtains or partial screens for bunks; gender-separate blocks with secure access

Climate & regional notes (PH, MY, KSA, and beyond)

- Philippines / Malaysia (hot-humid): anti-corrosion coatings, closed-cell foam + vapor control, typhoon tie-downs; mold-resistant finishes

- Saudi Arabia (hot-arid): high-albedo roofs, deep shading, sand-proof filters, UV-stable gaskets; specify desert-grade coatings

- Temperate (USA/EU): energy-code insulation, thermal breaks, ERV/HRV for IAQ; snow/wind checks

These climate choices explain price gaps even for “identical” floor plans.

Price drivers (budget the right way)

Avoid global one-liners; instead price these buckets:

- Structure: frame gauge, stacking capability, wind/seismic anchoring

- Envelope: insulation type/thickness, thermal breaks, window/door U-values

- MEP: electrics, HVAC tonnage, WASH fixtures, hot-water solution, pumps

- Finishes: floors (SPC/vinyl/anti-slip), washable wall panels, acoustic ceilings

- Logistics: ocean freight, port charges, last-mile haulage, cranes, container store shipping if using standard freight

- Scale & spares: multi-unit discounts, spare customised containers parts (hinges, locks, seals)

Pro tip: Ask vendors for itemized quotes. Cheaper offers often cut insulation thickness, glazing spec, or WASH quality.

Compliance & safety: pass inspection the first time

- Fire: rated walls/doors where required; smoke/CO detection; extinguishers and hydrants

- Egress: door widths, illuminated signs, no dead-end corridors

- Water & sanitation: backflow prevention, vent stacks, anti-slip floors with coved skirting, separation of clean/dirty zones

- Electrical: earthing, RCD/GFCI, labeled panels, emergency lighting

- Accessibility: ramps, thresholds, turning radii, fixture heights

- Security: perimeter fencing, controlled gates, CCTV in public areas, lighting

Power, water, waste: the hidden backbone

- Power: gensets sized for peak + surge; solar pre-wire for daytime loads; UPS for clinic IT

- Water: storage tanks, UV filtration or chlorination; booster pumps

- Waste: grey/blackwater treatment (septic vs MBBR/MBR); grease traps; solid waste segregation

- IT: centralized rack with ventilation; Wi-Fi mesh for admin/classrooms; surge protection

Buying from factories (domestic vs imports)

Domestic (e.g., folding house manufacturers USA)

- Pros: code familiarity, quick service calls

- Consider: higher unit price, catalog limits

Imports (e.g., container house from china, container houses china, container house china)

- Pros: scale, options (flat pack/foldable/expandable), competitive pricing

- Consider: lead time, port logistics; book pre-shipment inspection

Due-diligence checklist

- Factory credentials (ISO/QMS, welding certs), recent third-party audits

- GA drawings, BOM, fire/electrical/watertightness reports

- Mock-up approvals (corner, bathroom, door set)

- Clear INCOTERMS (EXW/FOB/CIF), insurance, staged payments (LC/Escrow)

- Spares kit and warranty SLAs in writing

- If you need unique branding or fixtures, request customised shipping containers scope early

Installation & commissioning (the short plan)

- Site prep — survey, soil bearing, foundations (pads/pier blocks), drainage

- Delivery & cranage — route checks, turning radii, taglines, lift plan

- Placement — level, inter-module joints, weatherproofing (flashings, thresholds)

- MEP hook-ups — power, water, sewage; pressure and insulation tests

- Fire/safety — signage, extinguishers, alarms, drills and muster points

- Handover — O&M manuals, training, spare parts, maintenance schedule

With trained crews, initial occupancy often starts within days for foldable hubs and within 1–3 weeks for larger flat pack compounds (local permitting varies).

Common pitfalls (and easy fixes)

- Under-spec insulation/HVAC → raise R-values, add shading, right-size tonnage

- No acoustic plan → upgrade partitions and door seals in dorms and clinics

- Ignoring last-mile costs → pre-book cranes, check road access, coordinate escorts

- Vague scope → one-page spec avoids “allowances” that bloat later

- Skipping QA → inspections catch leaks, mis-wired circuits, and weak hinges before shipment

FAQs (People Also Ask)

How many people fit in one dorm unit?

A 40-ft dorm typically fits 8–12 bunks with proper aisles, ventilation, and storage. Check egress width and occupancy limits by code.

Are container camps safe and compliant?

Yes—when built to code: rated assemblies, correct egress, anchored foundations, tested electrics, and hygienic WASH with proper venting.

What’s the fastest way to deploy a camp?

Use foldable units for dorms and WASH, with a small container office and clinic pod. Expand with flat pack for longer stays.

Can we add classrooms and clinics later?

Absolutely. The same platform builds container classroom blocks and container hospital pods. Standardized footprints make phasing easy.

Do container camps work in typhoon or desert regions?

Yes—specify climate-smart insulation, anti-corrosion systems, and tie-downs (typhoon) or sand-proof filtration and UV-resistant seals (desert).

Rent or buy?

Short deployments favor rental; long projects or custom layouts favor purchase. Hybrid fleets are common.