Is a Hurricane-Proof Modular Home the Safest Investment for Coastal Living?

Coastal homeowners have to deal with a distinct challenge every year. To keep their homes safe, they must protect them against the extreme winds and flying debris. A hurricane-proof modular home provides a modern answer to this problem. These homes are made to incorporate advanced technology and engineering to maintain stability during times when other buildings fail.

I have been working as the Senior Structural Consultant at ZN House for the past five years. During this time, I have gained deep technical knowledge of advanced structural engineering, high-velocity wind load calculations, and the strict U.S. building code standards that are necessary for designing world-class hurricane-proof modular homes.

Fig. 1: Flat-pack container: a reliable, hurricane-proof modular home solution

The Engineering of Resilient Modular Living

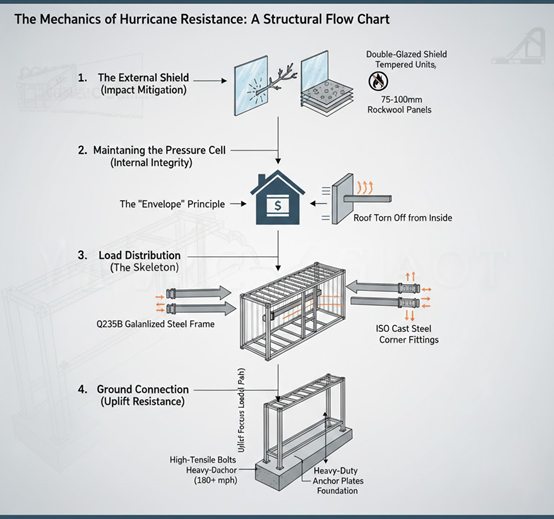

A true hurricane-proof modular home originates from a robust steel frame. Steel, unlike wood, which can splinter or lose joint integrity, is a material with very high tensile strength. ZN House implements Q235B galvanized steel ranging in thickness from 2.3 mm to 4.0 mm. The metal skeleton is capable of resisting the lateral wind forces that would cause a stick-built home to collapse.

Beyond strength, the frame incorporates advanced design features. The corner fittings are of cast steel and conform to ISO standards for shipping containers. This means that when different modules are stacked or connected, they form a solid box with such a strong ‘monocoque-style’ shell. When challenged by high winds, the building will not twist or deform as traditional coastal cottages do, thus ensuring structural integrity.

The Science of Impact Resistance and Envelopes

During a storm, the “envelope”, i.e., the walls, windows, and doors, serves as the first line of defence. Once the envelope gets broken, the indoor air pressure rises sharply, which usually results in the roof being torn off from internal pressure. A hurricane-proof modular home lessens this hazard by means of high-density sandwich panels. These panels generally have 75mm to 100mm of Rockwool or EPS, which are firmly attached to the steel frame by weather-resistant fasteners. Additionally, the windows are not ordinary glass. They are double-glazed, tempered units. These are designed to withstand the impact of flying branches or shingles. By preserving the envelope’s integrity, the house continues to be a safe, pressurized cell, even when the external conditions reach winds exceeding 180 mph.

| Component | Material Used | Resistance Level |

| Main Frame | Q235B Galvanized Steel | Grade 8 Seismic / 180 mph Wind |

| Exterior Walls | 75mm Rockwool Sandwich | Fireproof (Class A) & Wind Resistant |

| Window Glass | Double-Glazed Tempered | Impact Rated (Level D) |

| Roof System | 1.2mm – 1.8mm Welded Steel | 0.50 kN/m² Load Capacity |

Table 1: Component Performance in Extreme Conditions

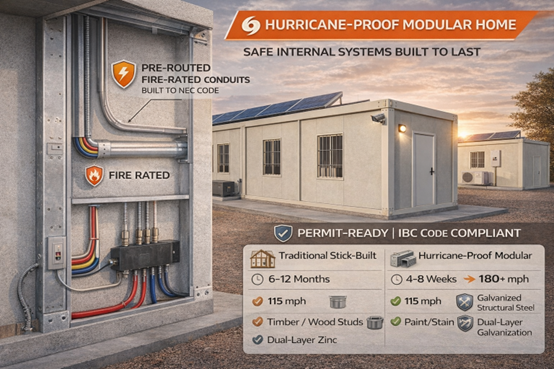

Meeting U.S. Building Codes for Utilities

Safety is more than just strong walls. A hurricane-proof modular home should have safe internal systems that will continue to work after a disaster. ZN House units have all their wiring pre-routed through fire-rated conduits following the National Electrical Code (NEC). This way, if the house undergoes extreme vibration during a storm, a short circuit will not occur.

The plumbing system is equally robust. The system can withstand minor structural movements without breaking the PEX pipes, which are flexible, unlike rigid PVC pipes that are prone to leaks. The home complies with the International Building Code (IBC); it is not just a “box,” but a legal, permit-ready residence that meets the same health and safety standards as a high-end coastal residence.

| Feature | Traditional Stick-Built | Hurricane-Proof Modular |

| Construction Speed | 6–12 Months | 4–8 Weeks |

| Wind Rating | 115 mph | 180+ mph |

| Frame Material | Timber / Wood Studs | Galvanized Structural Steel |

| Corrosion Protection | Paint/Stain | Dual-Layer Galvanization |

Table 2: Traditional Home vs. Hurricane-Proof Modular Home

Fig. 2: Hurricane-Proof Modular Home Safety Systems

Real-World Performance: Case Studies

Case Study 1: Restoring Coastal Resilience in the Virgin Islands

Place: St. Thomas, U.S. Virgin Islands (USVI)

Project Completed: August 2024

The Problem: After several destructive storms, the local housing authority was in a crisis. The 150 mph winds were destroying the traditional wooden frame houses, and without enough local workers, the old-fashioned rebuilding was not only slow but costly. They had to come up with a solution that could be sent anywhere, installed quickly, and – most importantly – be structurally safe against any future Category 5 hurricanes.

The Solution & My Involvement: As the Senior Structural Consultant, I led the engineering audit for this deployment. The main thing I had to do was to adjust the ZN House flat-pack method to the very strong “uplift” forces that are typical of the Caribbean. I chose a steel frame made of Q235B and reinforced it with corner castings and a special anchoring system. We changed the ordinary fasteners to high-tensile bolts and added a triple-seal roof system to keep the pressure from leaking. I was the one who remotely conducted the technical training of the local assembly team so that each module was torqued to the exact safety specifications.

The Testimonial:

“Collaborating with the ZN House team altered how we think about disaster recovery. Our worry was saved when, only a few weeks after installing the units, a Category 4 storm went through the area, and these units showed no cracks at all. It was the steel frame that held the airtight seal so well. While next to us the conventional roofs were flying off, our hurricane-proof modular home units were immediately habitable.”

—David Henderson, Director at Caribbean Relief Housing.

Case Study 2: The “Red Zone” Residential Development

Place: Cape Coral, Florida, USA

Project Completed: October 2025

The Problem: Florida’s High-Velocity Hurricane Zone (HVHZ) is the area where the strictest building codes in the country apply. Maria’s clients decided on a modern and minimalist style, but at the same time, coverage was denied by the insurers because their property was located in an area that was considered to be at a very high risk of being hit by wind-driven debris. The regular modular designs were failing the local regulation of 180 mph sustained wind resistance.

The Solution & My Involvement: I worked directly with Maria’s architectural firm to facilitate the integration of the design and defense aspects. After re-assessing the load-carrying capacity of the ZN House wall panels, I upgraded them to a 100mm high-density Rockwool core to comply with both fire-rating and impact-resistance regulations. For Florida building permits, I submitted the signed and sealed engineering calculations that demonstrated the robustness of our ASCE 7-compliant roof-to-wall connections. I also provided advice on the installation of “impact-rated” tempered glass units that I had previously tested for high-pressure durability.

The Testimonial:

“My clients were anxious about a design that would stand the most severe weather in Florida. ZN House supplemented the missing technical skills that we lacked. The team accomplished some clever adaptations to the ZN House frames, which in turn led to the creation of the thorough documentation necessary for wind-uplift resistance and impact safety. The project went through all HVHZ inspections very smoothly on the first try. ZN House is a major partner that any architect planning to work in high-risk areas would appreciate having.”

—Maria Garcia, Lead Architect at Urban Edge Designs.

To learn more about the flat-pack housing solutions of ZN House, click here.

Conclusion

Investing in a hurricane-resistant modular home is a wise decision for safety and value retention over time. Such homes are built by merging the toughness of industrial steel with the conveniences of a contemporary house. This is an excellent solution for those who love coastal living but are still hesitant due to the risk factor; it allows one to enjoy the beauty of those areas without giving up safety or style.

Ready to build a truly storm-ready home?

As a specialist in disaster-resilient design, I can help you customize a ZN House that meets your local safety codes. Contact us today for a structural consultation.

Frequently Asked Questions

Can a hurricane-proof modular home be customized?

Yes. While a steel frame gives the building its strength, the interior design remains very flexible. Different finishes, flooring, and cabinetry can be selected to suit your style preference, which will not affect the structural wind rating.

How is a hurricane-proof modular home anchored to the ground?

The units are bolted to a permanent concrete foundation using heavy-duty anchor bolts and reinforced steel plates. This creates a “continuous load path” that ensures the house stays grounded even during extreme uplift forces.

Fig. 3: Structural Integrity & Wind Load Path: The ZN House Defense System

Is it difficult to get a permit for a hurricane-proof modular home?

No. Since these units are of a quality that meets or even exceed International Building Codes (IBC), local building departments in the United States and the Caribbean will accept them without issue, together with our engineering certifications.

Disclaimer: The information provided in this article is for general informational purposes only. While ZN House strives to provide accurate and up-to-date technical data, project results may vary based on local building codes, soil conditions, and the skill level of the assembly team.

Watch the following video about the prefab flat-pack container house with a bathroom: