Prefabricated Resettlement Homes: A Reliable Solution for Government Housing Projects

Government housing programs are often caught in a dilemma of speed, cost, and quality. After natural calamities or urban renewal, there is a critical need for shelters. Prefabricated resettlement houses have, quite obviously, been the first option chosen for large-scale housing projects. Such houses offer homeowners a stable and secure environment, but at the same time, they are easy to deploy in different areas. They represent a viable, versatile alternative to the traditional way of construction. This article discusses how modular technology can be used in government resettlement programs that are very demanding.

With more than six years of deep involvement in modular architecture and large-scale resettlement logistics, I have directed the application of environmentally friendly housing projects worldwide. My area of expertise is enhancing the durability and economic nature of modular constructions. Throughout my career, I have handled the project management and technical design of the studies cited below, and I can vouch for their compliance with the highest safety and comfort standards.

The Strategic Value of Modular Systems in Resettlement

Governments are looking for solutions that can be scaled and remain effective over the long run. Resettlement homes made of prefabricated components have a slope-roof design that is highly functional in areas that get a lot of rainfall. This feature allows water to be drained very efficiently. In addition to that, because of being modular, it can be quickly expanded. What used to be a small neighbourhood can be a big housing estate in just a few weeks.

UN-Habitat reports that worldwide, the demand for cost-friendly housing is escalating very fast. Modular construction is being identified as one of the major ways to solve this problem. By using factory-controlled environments, we can minimize the waste of materials. This is why prefabricated resettlement housing can be considered as a green option for public works.

Technical Specifications and Material Quality

The durability of these homes is largely dependent on the quality of the steel and insulation used. Using high-grade materials guarantees the protection of the residents. The table below outlines the standard components of these units, derived from the technical data of ZN House’s production line.

| Component | Specification Details | Material Grade |

| Main Frame | Double 8# C steel combination (1.5mm wall thickness) | Q235 Galvanized |

| Roofing | 950 type 50mm rock wool sandwich corrugated board | 0.20mm Steel Plate |

| Wall Panels | 50mm rock wool tongue and groove sandwich panel | 0.20mm Steel Plate |

| Beams | Herringbone and bottom beams (8# C steel) | Galvanized & Painted |

| Windows | 1740 * 925 plastic steel window | Standard Industrial |

| Doors | Single-frame steel anti-theft door | High-Security Steel |

Table 1: Material Specifications for Resettlement Units

Ensuring Structural Stability

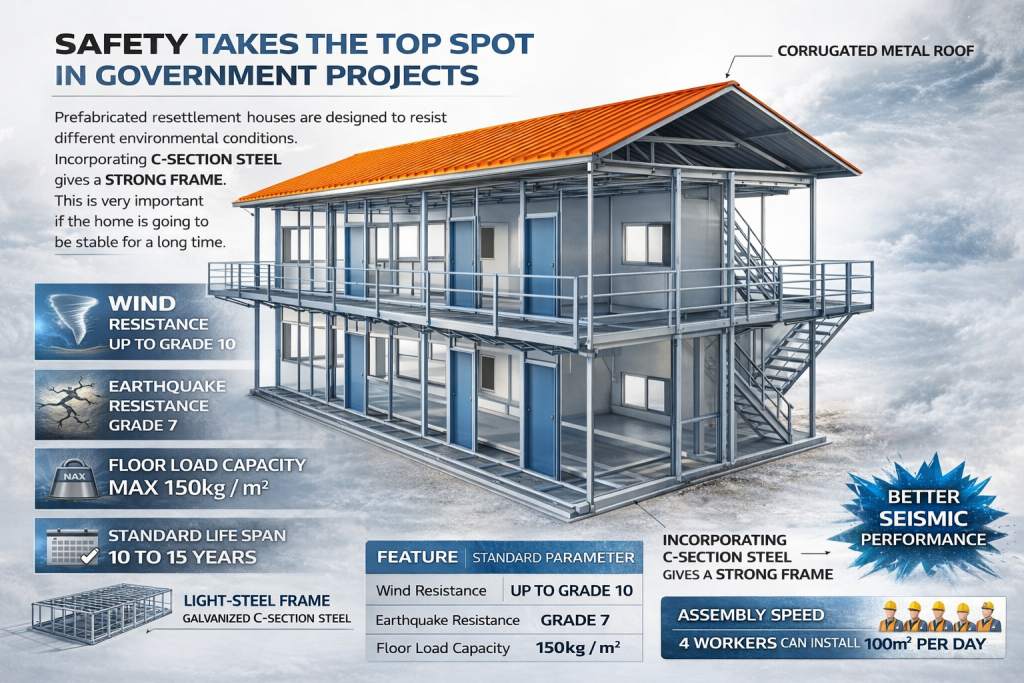

Safety takes the top spot among the factors in government projects. Prefabricated resettlement houses are designed to resist different environmental conditions. Incorporating C-section steel gives a strong frame. This is very important if the home is going to be stable for a long time. A study in the Journal of Modern Civil Engineering states that light-steel frames have better seismic performance than traditional masonry in temporary housing situations.

| Feature | Standard Parameter |

| Wind Resistance | Up to Grade 10 |

| Earthquake Resistance | Grade 7 |

| Floor Load Capacity | 150kg / m² |

| Standard Life Span | 10 to 15 years |

| Assembly Speed | 4 workers can install 100m² per day |

Table 2: Performance and Dimensional Data of Prefabricated Resettlement Homes

Efficient Disaster Relief Housing and Cost Efficiency

Budget constraints are a reality for most public sectors. Prefabricated resettlement houses provide a lower cost per square foot as compared to permanent cement buildings. Since the parts are prefabricated, the cost of on-site labour is extremely low. These inexpensive modular housing systems enable governments to accommodate more people with the same amount of money.

The rapid assembly resettlement units also have the feature of being portable. In case a resettlement site is no longer required, the units can be taken down. Then, they can be transported to a new place. Such adaptability offers a great return on investment to the government agencies.

Case Studies: Real-World Implementation

Case Study 1: Southeast Asia Post-Flood Recovery

Location: Kelantan, Malaysia

Time: October 2021

The Problem: The heavy monsoon season in Kelantan brought about disastrous flash flooding that wiped out the local infrastructure of 400 families. The local government ran into a humanitarian crisis when there were no houses available for those affected by the flood. They had to come up with a solution that would offer immediate sanitation, privacy, and protection from the persistent heavy rains. The local government only had 30 days, a very strict deadline, to complete the work before the next major weather front came. Normal construction was out of the question because of the soaked ground condition and the very limited time.

The Solution: In my capacity as the project lead, I took the initiative to organize the fast distribution of 200 prefabricated houses for resettlement. Our design team came up with a unique slope-roof, which allowed quick water drainage and also helped in preventing leakages due to the roof. In choosing the materials for the homes, 50mm rock wool sandwich panels, which have excellent thermal insulating properties and at the same time keep the moisture out, were selected to combat the high humidity and the tropical heat. My team and I really got our hands dirty on-site. We directly oversaw the erection of the Q235 galvanized steel frames, making sure the stability of each unit was guaranteed, even on the flood-affected and thus, loosened ground.

Testimonial: “The speed with which delivery was made was nothing short of life-saving. The ZN House team gave us units that had better cooling and were more private than the tents that we had used in the past.”

—Ahmad Razak, Regional Disaster Relief Coordinator

Case Study 2: Industrial Worker Resettlement

Location: Al Jubail, Saudi Arabia

Time: March 2023

The Problem: An extensive city-conversion initiative necessitated the prompt evacuation of a slum area. The administration was going to relocate 1,000 workers temporarily during the changeover. The main difficulties were the harsh desert heat, sometimes going over 45 °C, and the very confined parcel of land for the housing location. In addition, a safety specification was imposed for main traffic routes to be accident-free zones in such a densely populated urban setting.

The Solution: I designed a multi-story arrangement by using two-story modular complexes in order to get the most out of the available land footprint. In order to fight the harsh desert heat, we used white-coated steel plates to reflect solar radiation and rock wool insulation for temperature control. I was the one who initially decided on installing C160 checkered steel plate corridors and staircases with reinforced beams as a non-slip, high-load-bearing surface capable of withstanding the daily employee traffic.

The use of double 8# C steel uprights not only made the two-story buildings capable of withstanding heavy desert wind loads but also made them stable against these loads for quite some time.

Testimonial: “The structural integrity of the triangular roof racks was strong. At the same time, through efficient teamwork and planning, we managed to relocate as many as a thousand people to safety in no time.”

— Sarah Al-Saud, Project Manager at Gulf Infra-Tech

To know more about the K-type House, visit our Product Page here.

Conclusion

Prefabricated resettlement homes are a symbol of the successful integration of engineering and humanitarian aid. They are a very humane, safe, and cost-effective solution to housing shortage problems. High-quality steel frames and rock wool insulation are the materials of choice in such projects to guarantee that the investment will be long-lasting. These modular constructions should not be regarded merely as stop-gap measures but as the basis for future, efficient urban planning.

If high-quality, scalable housing solutions are what you are after, ZN House is poised to help. Our experts are proficient in the quick delivery of modular houses to cater to government and business needs. Feel free to get in touch with us today to talk over your requirements and get an offer.

FAQs

How long does it take to assemble prefabricated resettlement homes on-site?

The assembly time for these homes is incredibly short. Usually, a group of four skilled workers can finish the housing project that covers about 100 square meters within one day. Such a fast construction rate is necessary to comply with government mandate deadlines and to provide shelter without delay.

Are prefabricated resettlement homes durable enough for extreme weather conditions?

Yes, they are a durable solution. These prefabricated resettlement homes’ slope-roof design is efficient in withstanding heavy rains and thus avoiding leaks in the long run. Besides, the 50mm rock wool panels offer excellent fire resistance and thermal insulation, so residents stay safe whether it is extremely hot or cold outside.

Can the interior layout of prefabricated resettlement homes be customized for specific projects?

Absolutely. The flexible layout of prefabricated resettlement homes permits different arrangements. You have the option to tailor the interior such that it offers private single-family units, large-scale community dormitories, or even mobile medical clinics and administrative offices in line with the specific requirements of the resettlement site.

Disclaimer: The technical data and materials shown in this publication are references from ZN House’s own production container. It should be understood that the specifications, materials, and technical data can vary depending on the particular project and regional standards.

If you want to see how the assembly process is done, watch this video of ZN House’s K-type container house: