The Evolution of Prefab Steel Container Housing

Modern construction is evolving. For a long time, brick and mortar were the only options for durability. Nowadays, prefab steel container housing is challenging this idea. Such buildings are more than just “boxes”; they are sophisticated modules that are designed for a worldwide market that demands fast and sustainable solutions. Through the use of eco-friendly modular housing, companies are now able to deliver top-notch living and working environments in half the time taken by conventional building methods.

Fig. 1: A Prefab Steel Container Housing Project in a Country Area

I have been working as the Senior Technical Consultant & Project Lead at ZN House with over 8 years of experience in the modular construction and prefab steel industry. I have directed container projects over 200 in different parts of the world. My key areas include structural integrity, optimizing thermal performance, and incorporating weather-resistant steel structures in harsh climates. This article presents practical insights based on my hands-on experience and in-depth knowledge of the field.

The Anatomy of a High-Performance Prefab Steel Container Housing

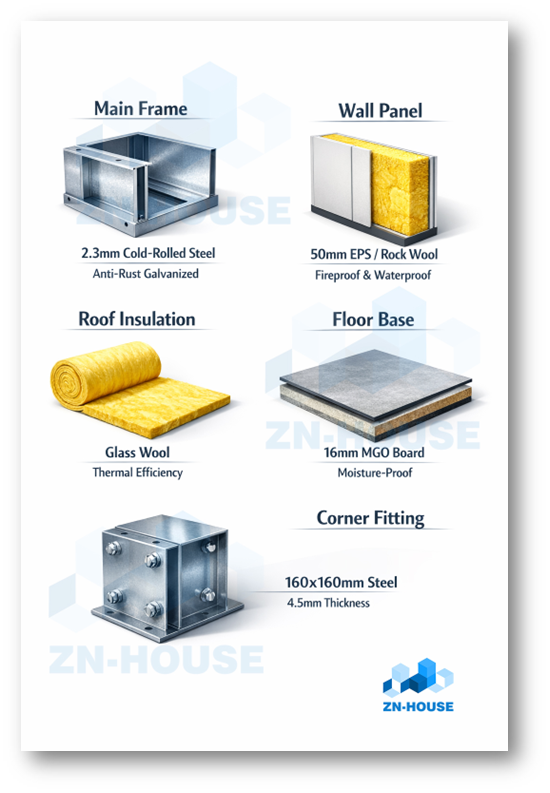

The strength of a component is primarily determined by its framework. Q235B and Q355B grade cold-rolled steel profiles from the main range are used for the main structure. These weather-resistant steel structures are further protected by anti-rust galvanization. This method guarantees a constant frame stability for a period exceeding 20 years.

As for the walls, 50mm to 100mm EPS or Rock Wool sandwich panels are installed. They contribute significantly to fire resistance and thermal regulation. A quick turnaround container unit should be able to give good service in different seasons, hence the reason for our inclusion of glass wool roof insulation and MGO fireproof floor boards.

| Component | Material | Key Feature |

| Main Frame | 2.3mm Cold-rolled Steel | Anti-rust Galvanized |

| Wall Panel | 50mm EPS / Rock Wool | Fireproof & Waterproof |

| Roof Insulation | Glass Wool | Thermal Efficiency |

| Floor Base | 16mm MGO Board | Moisture-proof |

| Corner Fitting | 160x160mm Steel | 4.5mm thickness |

Table 1: Material Specifications & Component Details

Fig. 2: Key Components of Modular Building Units

Prefab Steel Container Housing Operational Efficiency and Deployment

Time is a key factor in construction. The Modular Building Institute’s research shows that the use of modular methods can lead to 30-50% shorter construction schedules. Also, Fortune Business Insights (2024) states that the market for such units is growing because of their ‘plug-and-play’ feature. Container units for rapid deployment are equipped with electrical wiring and plumbing facilities in our factory, thus minimizing the labour costs on-site to a great extent.

| Metric | Performance Level | Standard Compliance |

| Wind Resistance | Grade 11 (120 km/h) | ISO 9001 Certified |

| Earthquake Resistance | Grade 8 | Seismic Stress Distribution |

| Roof Load | 1.0 – 1.5 kn/m² | Snow & Rain Resilience |

| Lifespan | 15 – 20+ Years | Galvanized Coating |

Table 2: Performance Ratings & Resistance

[Notes: Grade 11 (120 km/h): Grade 11 (120 km/h) wind resistance, tested according to ISO 4355: Wind Actions on Structures.

Case Studies: Direct Project Insights

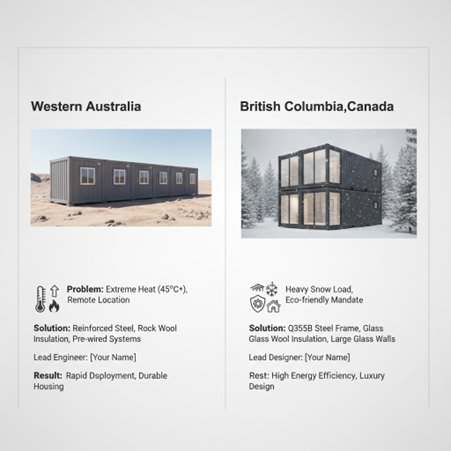

Having been at the forefront of modular developments for 8 years, I believe the key to success is breaking down site-specific problems and solving them with factory-precision engineering. Here are two examples of projects where I was fully in charge of converting the plans into the physical structures.

Case Study 1: High-Heat Industrial Housing – Western Australia

Location: Pilbara Region, WA

Time: September 2022

The Problem: The client planned to send about 40 work units for a region where the temperature normally exceeds 45°C. Local conventional construction methods will not be possible as the area is very remote and the extreme heat will pose a double risk – to the safety of the workers and to the integrity of the materials.

The Solution: I was responsible for the tailored prefab steel container housing solution combination of 100mm high-density Rock Wool insulation and exterior coatings with a special reflective finish. We went with weather-proof steel structures that had cooling ducts made of reinforced material. To prevent heat-induced waiting during the construction phase, we pre-installed AU-standard electrical systems in our factory, which is under strict environmental control.

Testimonial: “The speed of deployment was incredible. [Your Name] made sure that the electrical systems and thermal barriers were compliant with local AU standards to a T. Even in the brutal Pilbara sun, our crew felt comfortable and at ease.”

— Marcus Thorne, Operations Manager, IronCore Mining Co. Ltd.

Case Study 2: Luxury Eco-Resort – British Columbia, Canada

The Problem: The client was seeking 15 luxurious units with floor-to-ceiling glass curtain walls. However, the site suffered from very heavy annual snowfall, so the buildings had to withstand a roof load of more than 1.5 kn/m and, at the same time, maintain a very high energy-efficiency level to comply with Canadian “Step Code” standards.

The Solution: I was in charge of the design of the reinforced frame that was made of Q355B grade steel, and we also had a double-layered glass wool roof insulation. We incorporated environmentally friendly modular housing solutions such as MGO fireproof floor boards and low-VOC finishes. I oversaw the structural stress tests myself to make sure that the units would be able to bear the weight of heavy mountain snow without any deformation.

Testimonial: “The snow load capacity was my biggest worry; however, ZN House’s engineering team came up with the extra reinforcements we required. We ended up with a luxurious appearance that is backed by the durability of the highest level.”

— Sarah Jenkins, Director, Summit Stay Ltd.

Fig. 3: The Case Studies at a Glance

To learn more about Modular Container House, visit our Product Page here.

Conclusion

Prefab steel container housing was traditionally considered a temporary solution only. Today, it is a permanent, standard solution for the modern world. ZN House engineers have completed over 200 modular projects globally, applying standardized Q235B/Q355B steel frames and ISO‑certified manufacturing processes. If your project is all about durability and fast execution, get in touch with us today, and we’ll demonstrate how our modules can be your match.

Ready to Elevate Your Next Project?

Traditional construction timelines shouldn’t be a limitation to your vision. Whether you are setting up a remote industrial site or a luxury eco-resort, ZN House supplies the engineering know-how and top-notch materials for a project that can be counted on to be successful. Contact our Technical Team today.

FAQ

How long do prefab steel buildings actually last?

Usually, a premium one that is constructed with a galvanized Q235B or Q355B steel frame and anti-corrosion coatings will have a working life of 15 to 20 years. Besides that, by means of systematic maintenance and the application of weather-resistant steel structures, these units could last structurally intact for a time period even longer, similar to semi-permanent traditional structures.

Are container-based houses safe during extreme weather like hurricanes or earthquakes?

Yes. They basically consist of a monolithic steel cage, which is why they have the best possible seismic and wind resistance, along with other advantages. Our units are certified for Grade 8 earthquake resistance and wind resistance tested to Grade 11 under ISO 9001 structural protocols, equivalent to sustained winds of 120 km/h. The built-in corner fittings, together with the cold-rolled steel profiles, guarantee that the structure will be stable even when subjected to high lateral and vertical stresses.

Can you stay warm in a metal container house during winter?

Absolutely. The mystery of the “metal box” in prefab steel container housing is explained with ultra-insulation layers. By using the walls made of the 50mm to 100mm Rock Wool or EPS sandwich panels and the glass wool in the roof, the units effectively manage the temperature. These eco-friendly, modular, prefabricated housing units not only successfully retain the heat in cold climates but also provide a cool atmosphere inside when the temperature outside is very high, as in Western Australia.

Disclaimer

Technical specifications and material grades, including material grades (Q235B/Q355B) and resistance ratings, are based on standard ZN House Prefab Steel Container Housing product data at the time of writing; actual performance may vary. It is up to the customers to ensure that their appliances follow the local building regulations, zoning, and permit requirements. External references and industry growth figures are provided for information only and are subject to change.

Technical Standards & References:

Modular Building Institute. 2023 Modular Construction Report.

ISO 4355: Wind Actions on Structures.

GB 50011‑2010: Chinese Seismic Design Code.

EN 1090: Execution of Steel Structures.

Australian NCC Volume 2: Structural Provisions for Modular Buildings.

Smith, R. (2019). Modular Construction: Engineering and Performance. Journal of Structural Engineering.