Why Is a Modular Container Toilet the Smarter Choice for Modern Sites?

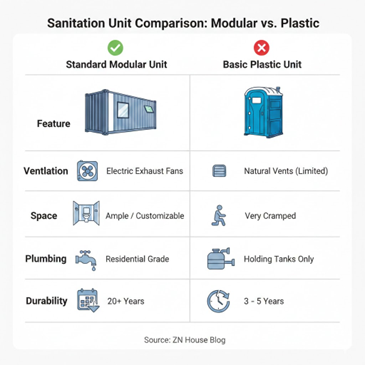

Sanitation plays a fundamental role in the planning of any site. It is essential to have proper facilities at your disposal, whether on a construction site or in a public park. Regular structures usually require very long times for completion. Plastic portable cabins, on the other hand, often seem small and unattractive. For these reasons, many people are switching to modular container toilets. These units combine the durability of a shipping container with the nice feeling of a home bathroom. Moreover, they can be set up very quickly and are super easy to clean and maintain.

As the Senior Solutions Engineer at ZN House, I have 7+ years of experience specializing in prefab infrastructure and modular design. I mainly focus on developing scalable sanitation systems for the industrial and commercial sectors. The result of my work is that each modular container toilet is safe, sturdy, and comfortable to use.

Why Choose a Modular Container Toilet?

The drive for modularity mainly comes from the need to deliver faster and better. It is not only that a modular container toilet is a temporary solution. Consequently, this is a very high-quality product that can be used for a long time. These are some of the elements that make these portable toilet units resistant to rust. Besides that, they have tightly packed insulation to keep temperatures at comfortable levels.

According to the Modular Building Institute (MBI) 2024 report, modular projects typically see a 30% to 50% reduction in schedule compared to site-built construction. Our specific flat-pack design allows a 4-person team to complete installation in under 6 hours

Technical Specifications and Materials

Knowing the technical details enables you to choose wisely. The backbone of these units is the structural frame. Top-notch factories employ Q235B steel for their main beams. This guarantees that the unit will be stable during transport and heavy usage.

| Component | Material Specification | Key Benefits |

| Main Frame | 3.0mm Galvanized Steel | High structural integrity and rust resistance. |

| Wall Panels | 50mm/75mm EPS or Rock Wool | Excellent thermal and sound insulation. |

| Floor System | Cement board + Anti-slip PVC | Fireproof, waterproof, and easy to clean. |

| Plumbing | Internal Concealed Piping | Protects pipes and enhances aesthetics. |

Table 1: Technical Specifications of a Modular Container Toilet

[Note: By using 75mm Rock Wool (density 100kg/m³), our units achieve a Thermal Conductivity of 0.035 W/m·K. In our Chile case study, this resulted in an interior temperature 15°C lower than the 45°C ambient desert heat without active AC.]

Designing for Comfort and Durability

A modular container toilet is required to be highly durable and resist rust as it will be subjected to wear and tear from heavy daily traffic. Colour steel sheets are a common choice for interior wall finishes. These are not only waterproof but also very easy to clean and disinfect. A high-speed exhaust fan is a staple feature in the ventilation system. This helps in keeping the toilet odour-free and retards the formation of mold and mildew. Adequate ventilation is one of the major elements of public health. According to the World Health Organization (WHO), adequate ventilation in sanitation facilities is a very effective way of reducing the transmission of airborne diseases. The frame uses 3.0mm Q235B galvanized steel, which provides a structural load capacity of 250kg/m² and a rust-resistance lifespan of 15+ years in high-humidity coastal environments

| Feature | Standard Option | Premium Option |

| Toilets | Ceramic Squat or Sit Type | Wall-hung Intelligent Units |

| Sinks | Stainless Steel or Ceramic | Integrated Marble Countertops |

| Lighting | LED Ceiling Lights | Motion-Sensor LED Strips |

| Partitions | Waterproof Phenolic Board | Frosted Glass or Compact Laminate |

Table 2: Interior Configuration Options for a Modular Container Toilet

Choosing the Right Installation Method

Installing prefab container toilets is very straightforward. You just require a ground that is either level or a concrete pad. The factory takes care of all internal wiring and plumbing. This “plug-and-play” approach is an ideal solution for project managers who have a lot on their plates. At the same time, it drastically cuts down the noise and waste on the site. According to an article published in the Modular Building Institute, modular construction techniques can lead to a decrease in site disturbance by as much as 90%.

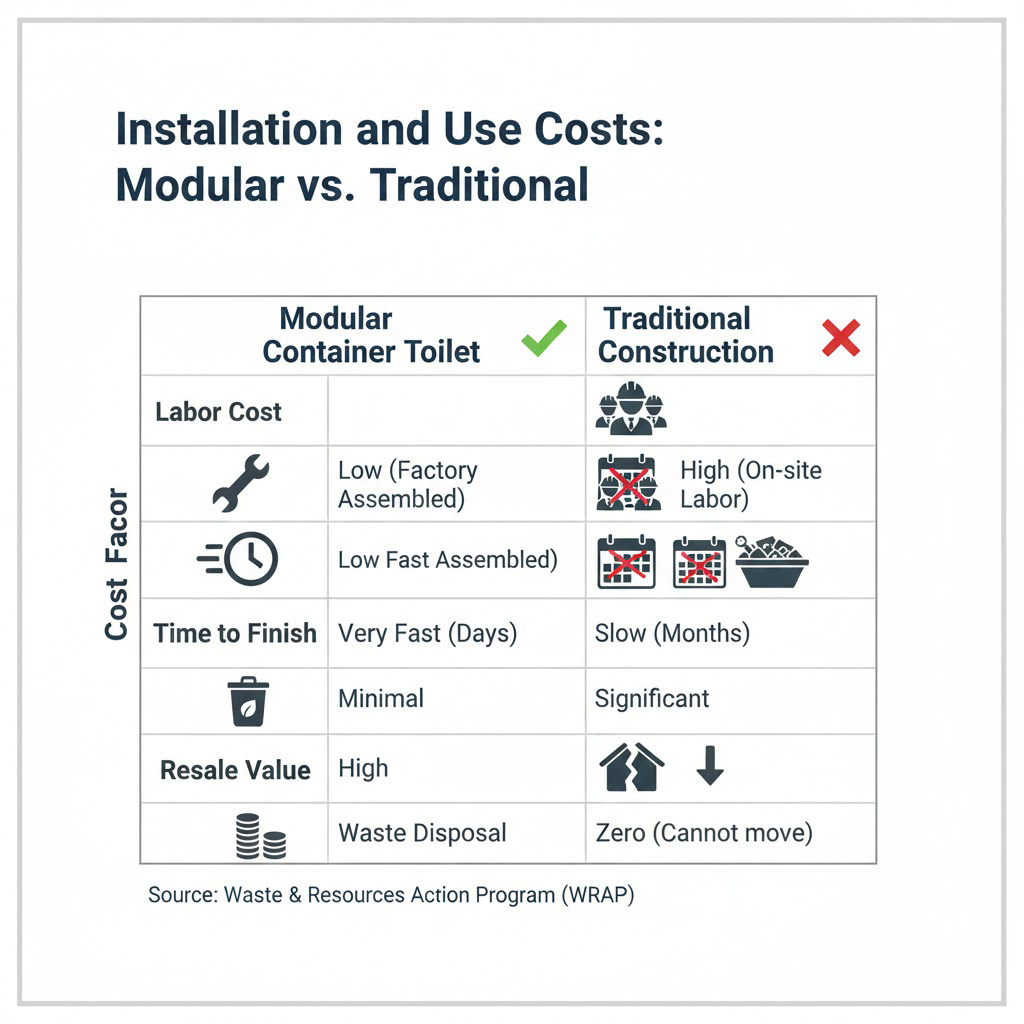

| Cost Factor | Modular Container Toilet | Traditional Construction |

| Labor Cost | Low (Factory Assembled) | High (On-site Labor) |

| Time to Finish | Very Fast (Days) | Slow (Months) |

| Waste Disposal | Minimal | Significant |

| Resale Value | High | Zero (Cannot move) |

Table 3: Installation and Use Costs of a Modular Container Toilet

Efficiency and Hygiene Standards

Good hygiene is essential. According to the WHO Guidelines on Sanitation and Health, adequate ventilation in sanitation facilities is a critical intervention for reducing the transmission of pathogens. Each modular container toilet is fitted with high-volume exhaust fans. The water pipes are concealed by panels. It gives a cleaner look, and also the pipes are protected from getting damaged.

Case Studies

Case Study 1: Remote Mining Camp Infrastructure

Location: Atacama Desert, Chile

Time: August 2024

A large mining operation in a hot desert region experienced a sanitation crisis toward the end of 2024. More than 200 individuals were living in the camp of this remote operation. Their plastic units were gradually becoming unusable as a result of the extremely high UV exposure and strong winds. The customer was looking for a modular container toilet solution that would be able to support continuous usage and yet be simple to clean.

The Challenge: The location was 500 miles away from the closest city, and the temperature had a tendency to rise above 45°C. The facility needed to be sturdy enough to withstand the wind but still be portable in case it needed to be relocated as the mine grew.

The Solution: We sent a dozen 20-foot containers with Rock Wool insulation of the heaviest kind. Apart from that, each container was made to feature a set of industrial exhaust fans and a galvanized steel frame that was both sturdy and reinforced.

The Result: The prefab container toilet was installed and up and running in only three days. According to the workers’ feedback, there was a 60% uplift in their level of satisfaction with the site hygiene condition. The insulation made the inside temperature 15 degrees lower than the outside air temperature.

Testimonial: “We dealt with rickety portable toilets for a long time. The switch to the modular units transformed everything. It is almost like they are normal bathrooms; they remain cool during the hot days, and the strong desert winds do not lift them.”

— Javier M., Site Operations Manager, Andean Minerals Corp.

Case Study 2: Urban Public Park Revitalization

Location: London, United Kingdom

Time: June 2025

Before a major ten-day summer festival, CityScape Urban Management Ltd. needed to upgrade the park facilities. The old brick-and-mortar restrooms were run down and even dangerous. Therefore, the company was looking for green portable sanitation units that would also blend with the contemporary look of the newly landscaped park.

The Challenge: They had to carry out the construction without shutting the park down for the public. Only two weeks were left until the festival started, so they were under a very strict deadline.

The Solution: Two tailor-made container units with exterior wood cladding and motion-sensor LED lighting were designed. These units were constructed off-site to limit the noise and dust in the park.

The Result: The bathroom units were delivered by flatbed vehicle and connected to utilities within six hours. Due to the installation of water-efficient toilets and the use of LED lights, the company experienced a very significant decrease in water and energy consumption. This project became a perfect example of how a modular container toilet can combine the luxurious comfort of a permanent facility with the quickness of a temporary solution.

Testimonial: “The level of efficiency was just amazing. In just one afternoon, we transformed a construction site into a fully functioning, beautiful restroom. Our visitors have been very impressed with the cleanliness.”

— Sarah T., Project Procurement Manager, CityScape Urban Management Ltd.

To know more about the modular prefabricated container bathroom, please visit our Product Page here.

Conclusion

A modular container toilet is an indispensable asset that can be used in different ways. It is capable of providing lasting value through its sturdiness and the requirement of very little maintenance. Portable sanitation units that are environmentally friendly and sustainable will be the site infrastructure in the future. They are a source of a clean, secure, and decent setting for all. Opting for strong modular bathroom solutions helps to keep your construction work going and your budget balanced.

Ready to give your site facilities a fresh look?

ZN House offers modular designs of the highest quality, fitted perfectly to your requirements. Whether it’s single units or big complexes, ZN House guarantees quality in every construction.

Let ZN House know what you’re planning, and they will give you a tailored quote.

Frequently Asked Questions (FAQ)

How do you clean a modular container toilet?

The floors and walls are waterproof. You can use ordinary cleaning chemicals or high-pressure water jets. The anti-slip PVC floor makes it safe and easy to maintain daily hygiene.

Is a permit required for prefab container toilet installation?

Permit regulations vary depending on the location. Still, since a modular container toilet is typically regarded as a temporary or movable structure, the procedure is generally quicker than a permanent construction.

Can the prefab container toilet units be connected to a septic tank?

Yes. You have the option to connect them to the local sewer lines or a septic tank. This adaptability makes them ideal for locations both in the city and in the countryside.

Disclaimer: The technical information and materials presented in this article are referencing ZN House’s own manufactured containers; specifications, materials, and technical data can differ.

Watch the following video on the prefabricated modular bathroom with 304 stainless steel floors: