The Evolution of Modern Living: A Deep Dive into Prefab Homes in Asia

The construction landscape across Asia is changing. The rapid urbanization and the need for sustainable housing have greatly challenged traditional building methods. Nowadays, prefab homes in Asia are not only a temporary measure; they signify a highly advanced, lasting solution for residential, commercial, and industrial requirements. From the lively streets of Manila to the industrial centres of Malaysia, modular technology is transforming our construction approach.

My role for over seven years has been that of a Senior Project Engineer at ZN House, where I have acquired in-depth knowledge in modular engineering and large-scale prefabricated construction. Having had the opportunity to manage the installation of thousands of container units across the Asia-Pacific region, my main focus has been on finding a balanced solution for promoting both technical efficiency and a comfortable architectural design. In fact, I make sure that any structure is able to achieve the best safety and environmental standards.

Understanding the Surge of Prefab Homes in Asia

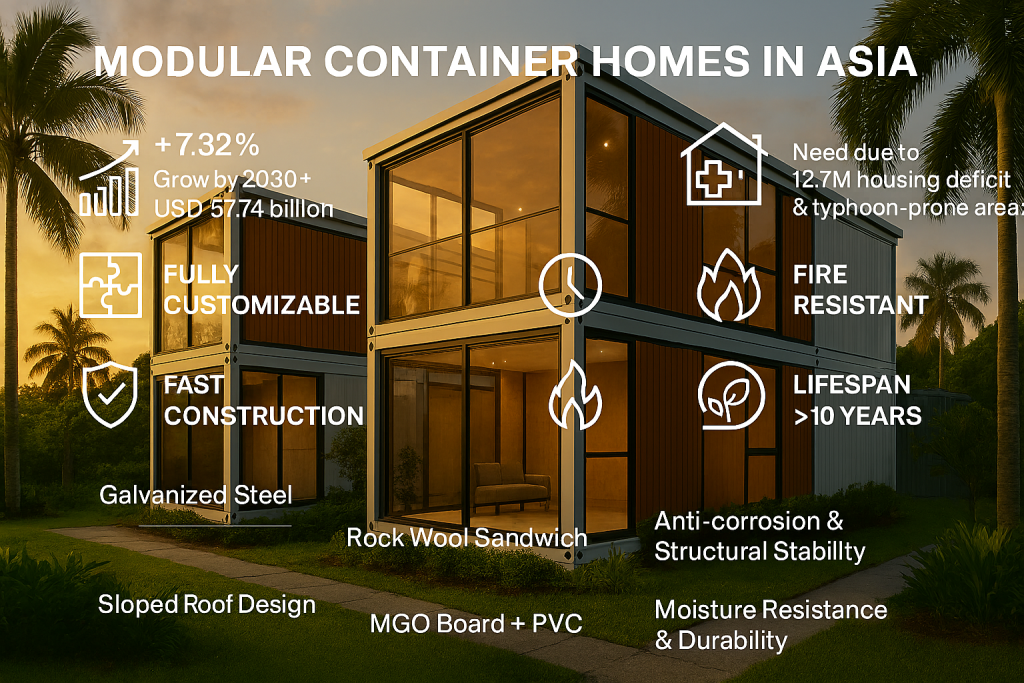

Overall, there are numerous reasons behind the growing need for prefab homes in Asia. For instance, according to MarketsandMarkets, by 2030, the Asia-Pacific modular construction market is expected to grow by 7.32% annually and is expected to reach USD 57.74 billion. This is due to the lack of 12.7 million housing units in countries such as Indonesia, as well as the need for housing that can be rapidly deployed in the Philippines, which is prone to typhoons.

In the developing world, the rapid modular container homes can do so much more. They can be completely customized, and in addition to construction speed, they are fire-resistant and can withstand earthquakes up to Grade 7. For developing countries that have highly unpredictable weather due to climate change, the galvanized steel frames of modern prefab units are corrosion-resistant, and the units have a lifespan of more than 20 years.

| Component | Specification | Benefit |

| Main Frame | Galvanized Steel (Q235/Q345) | Anti-corrosion & Structural Stability |

| Wall Panel | 50mm-100mm Rock Wool Sandwich | Fireproof & Thermal Insulation |

| Roof System | Sloped Drainage Design | Water Leakage Prevention |

| Floor Base | 18mm MGO Board + PVC Finish | Moisture Resistance & Durability |

| Wind Resistance | Up to 100 km/h | Suitable for Tropical Storm Areas |

Table 1: Technical Specifications of Standard Prefab Units

Sustainable Prefab Housing Trends in 2024-2025

Sustainability is now in trend, especially in prefab housing construction. While traditional construction is known for its waste, modular manufacturing only generates 15% material waste. The Asian Development Bank states that pre-finished volumetric construction (PPVC) reduces on-site construction workers and heavy construction machines, which helps lower the construction site carbon footprint.

The trend in Southeast Asia is expandable and flat-pack designs. These units have high efficiency in logistics. For example, a 20ft expandable unit can be transported in a compact form and can be expanded on-site to increase the floor area by 2 to 3 times within minutes.

| Feature | Traditional Brick-Concrete | Prefab Modular House |

| Construction Time | 6–12 Months | 1–4 Weeks |

| Environmental Impact | High Waste & Dust | Low Waste (Factory Controlled) |

| Relocatability | Impossible | Highly Portable |

| Cost Predictability | Variable (Labor/Weather) | Fixed (Factory Pricing) |

| Labor Requirement | High On-site Labor | Minimal On-site Assembly |

Table 2: Comparison of Construction Methods

Prefabricated Dormitory Construction Asia: Meeting Industrial Demand

Prefabricated dormitory construction in Asia is one of the major uses of this technology. The Qatar World Cup Fan Village and industrial worker camps in Malaysia demonstrate that speed can go hand in hand with quality. For example, these projects use two-layer folding structures, which take less than 10 minutes to install per unit.

Real-World Impact: Case Studies

Case Study 1: Coastal Community Recovery, Philippines (2022)

The Problem: A municipal department in charge of rebuilding a poor coastal community hit hard by a typhoon had very little budget for the project and less than 60 days to complete it.

The Solution: I carried out the installation of 50 custom-made container homes, each 20ft in size. We installed a reinforced drainage system and applied anti-corrosion coatings to make the structures resistant to the salty sea air.

The Result: Residents were able to move in after just 45 days. Using a modular design helped us save 30% of costs against traditional rebuilds.

Testimonial: “The coordination was smooth. ZN House provided resilient homes in which our community can at last be secure.”

— Maria Santos, Project Coordinator, Local Government Unit (LGU), The Philippines

Case Study 2: Industrial Workforce Hub, Malaysia (2023)

The Problem: A manufacturing plant needed a two-story dormitory to accommodate 200 workers. However, the land available was small, and the environmental regulations were quite strict.

The Solution: We rolled out a 2-layer folding container system solution. The thickness when the unit is folded is only 0. 4m for each unit, thus allowing us to ship more units per truck and also lowering our carbon footprint.

The Result: The whole complex was completed with only 10 days of work on-site.

Testimonial: “One of the most impressive things was the speed at which the installation was done. The thermal insulation certainly helps to keep the place cool, which is a major plus in the Malaysian heat.”

— Tan Wei Leong, Operations Manager, TechLogistics Sdn Bhd.

To know more about our prefab container housing project in Asian countries, please visit here.

Conclusion

The future of prefab homes in Asia looks very promising. With the use of advanced technology in manufacturing, together with eco-friendly methods, we are able to quickly address the issue of housing shortage. From a luxurious villa to a huge worker camp, modular housing can give you the versatility and sturdiness required in today’s world.

Should you decide to embark on your next venture, the crew of ZN House will gladly be your partner to provide you with the know-how and top-notch containers essential for your success.

Frequently Asked Questions (FAQs)

How long do prefab homes in Asia typically last?

Using good maintenance and quality materials like galvanized steel and rock wool insulation, a prefab container house can be serviceable for more than 20 years.

Are prefab houses safe during earthquakes?

Yes, it is true that modular steel buildings are flexible by nature. Our products are seismic Grade 7 tested, which makes them safer even than traditional masonry ones.

3. Can I customize the interior of a container home?

Definitely. The frame is pre-designed and locked-in, but the interior can be packed with high-end finishes, have a built-in kitchen, a complete bathroom, and a carefully planned electrical system that can even be compliant with the local codes.

Disclaimer: The technical data and materials referenced in this article are ZN House’s own manufactured container products. Specifications, materials, and technical data may vary according to individual project needs and local regulations.

Watch this video to see why Southeast Asia loves our slope roof containers: simple assembly and superior design.